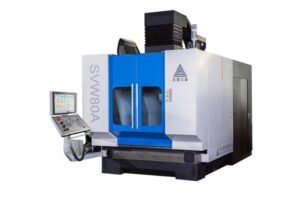

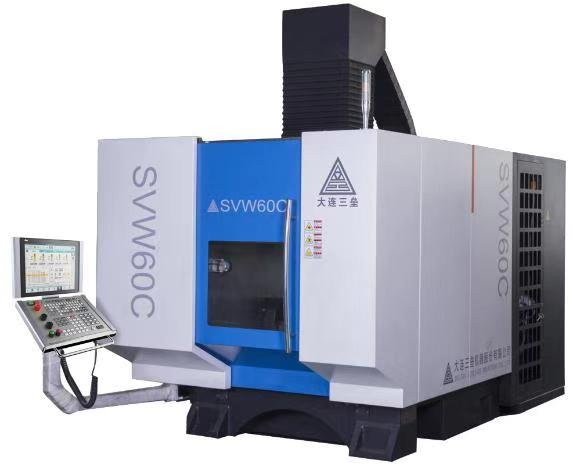

Description

The SVW is a cradle-type vertical five-axis machining center. It comes standard with the HEIDENHAIN iTNC530 CNC system, supplemented by a HEIDENHAIN optical scale for fully closed-loop operation. The high-power servo motor and torque motor direct drive ensure high positioning accuracy (compliant with the German VDI/DGQ3441 standard), fast response speed (acceleration of 5 m/s²), and five-axis simultaneous machining. The machine is also equipped with an automatic tool changer, fully demonstrating efficient and automated machining.

The machine’s linear feed axes (X, Y, and Z) utilize an internationally advanced “box-in-box” design and are each supported by four guide rails, ensuring rigidity during roughing and precision during finishing. The machine achieves five-axis simultaneous motion through left-right movement of the ram (X-axis), forward-backward movement of the crossbeam (Y-axis), vertical movement of the ram (Z-axis), tilting of the cradle-type turntable (A-axis), and rotation of the worktable (C-axis). The entire machine tool consists of a bed, column, crossbeam, ram box, ram, pneumatic system, automatic lubrication system, hydraulic system, cooling and chip removal system, electrical CNC system, detection system, and a fully enclosed protective system.

The machine tool comes standard with an imported electric spindle with central water outlet, enabling automatic spindle loosening and broaching. The machine’s X, Y, and Z linear feed axes utilize servo motors driven by synchronous belts to rotate ball screws. The A and C axes utilize torque motor direct drive and synchronous drive technology, eliminating transmission backlash and achieving high precision and responsiveness.

The machine tool comes standard with a water cooler, cutting fluid paper filter, chip conveyor, and chip car. Optional automatic measuring devices, fixtures, and tools can be customized to meet customer needs, providing a turnkey machine tool solution.

Reviews

There are no reviews yet.