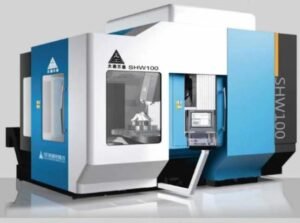

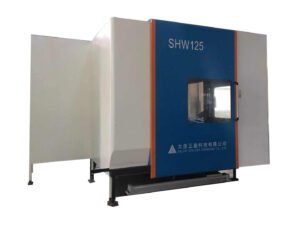

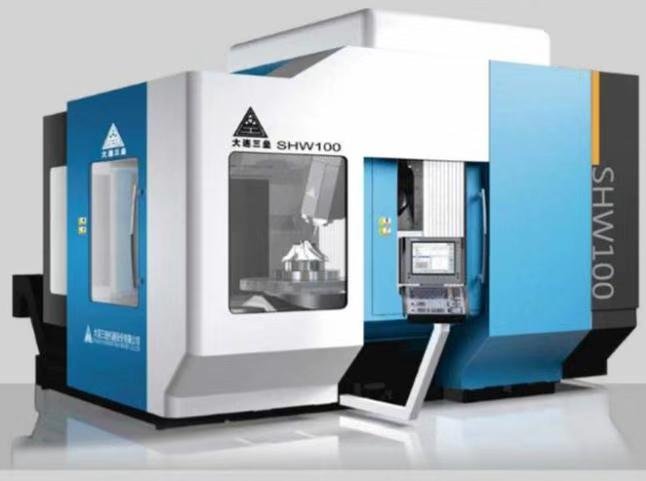

Description

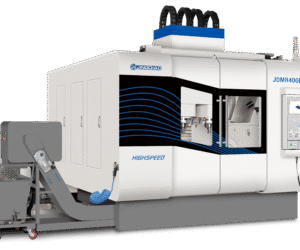

The SHW model is a five-axis machining center with a vertical-horizontal spindle conversion. It comes standard with the Heidenhain iTNC530 CNC system, supplemented by a Heidenhain optical scale for fully closed-loop operation. Its high-power Siemens servo motor direct drive delivers high positioning accuracy (compliant with German VDI/DGQ3441 standards), fast response speed (acceleration of 5 m/s²), and five-axis simultaneous machining. It is also equipped with an automatic tool changer, fully embodying efficient and automated machining.

The machine achieves five-axis simultaneous motion through the left-right movement of the slide (X-axis), the forward and backward movement of the worktable (Y-axis), the vertical movement of the spindle (Z-axis), the rotation of the worktable (C-axis), and the rotation of the milling head (B-axis). The entire machine consists of a bed, column, slide, rotary table, milling head, pneumatic system, automatic lubrication system, chip removal and cooling system, electrical system, and a fully enclosed protective system.

The machine comes standard with an imported electric spindle featuring central water outlet, enabling automatic spindle loosening and broaching. The X, Y, and Z linear feed axes utilize servo motors directly driving ball screws through couplings. The B-axis rotates using a servo motor driving a mechanical reduction mechanism, while the C-axis rotates using a servo motor driving a worm gear, resulting in a highly precise and rigid transmission system.

The machine comes standard with a water cooler, a cutting fluid paper filter, a chip conveyor, and a chip car. Optional automatic measuring devices, fixtures, and tooling can be customized to meet customer needs, enabling a turnkey machine solution.

Reviews

There are no reviews yet.