Description

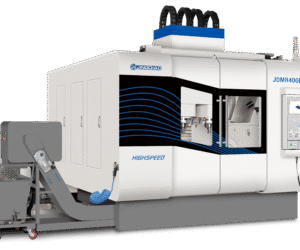

Five-axis machine tools can complete pentahedral machining of workpieces in a single clamping operation, making them particularly well-suited for flexible production of high-mix, low-volume products. The application of five-axis intelligent flexible production lines will significantly reduce the number of machine tools, transforming traditional manufacturing models. A single machine tool can replace an entire production line, improving processing efficiency while reducing factory floor space and the number of operators and maintenance personnel. Five-axis intelligent flexible production lines offer the advantages of adapting to part variability, lowering manufacturing costs, optimizing manufacturing system efficiency, and enabling rapid response, thereby effectively enhancing a company’s manufacturing capabilities and competitiveness.

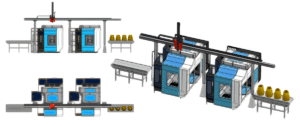

The five-axis flexible production line primarily consists of a five-axis machining center, a handling robot, visual monitoring and inspection, a quick fixture changer, and an automatic loading system. The production line can be equipped with workpiece inspection, tool detection and monitoring, and workpiece deburring devices, enabling comprehensive processing from rough to finished product. By collecting dynamic information from the flexible line and enabling networked and information-based management of the production process, it can be integrated with the shop floor management system, establishing a digital management platform and ultimately creating an intelligent, networked, and flexible smart factory.

Our company can provide overall industry solutions and turnkey projects according to customer needs.

Reviews

There are no reviews yet.